With its energy-saving features, built-in frost protection, and excellent life expectancy, it’s rare to see a fault code on an Ideal Logic Boiler. When an Ideal Logic Boiler fault code appears, it is often minor. This quick guide introduces homeowners to the most common fault codes with Ideal Logic Boilers, and explains what to do about them.

F1 Low Water Pressure

It’s likely that you’ll notice a problem in your system long before an F1 code appears. In an Ideal Logic Boiler, the F1 code means that the water pressure is too low. The symptoms are a struggling system, lacklustre heat, and increased energy bills. There are many reasons why this may happen. Leaks are the number one cause of low water pressure, and these can be hard to identify as they may be anywhere in the entire system. However, it is also worth adjusting the filling loop to see whether this solves the issue.

L2 Blocked Condensation

Blocked condensate pipes are the leading cause of boiler faults. Signified by Ideal Logic Boiler fault code L2, there are several reasons why a condensate pipe may become blocked. The main culprits are ice, sludge, limescale, and corrosion. Frozen pipes can be prevented with standard insulation, while the best antidote to other types of blockages is a system power flush. Annual boiler servicing can identify Ideal Logic condensate pipe issues long before they become an L2 code.

F9 Combustion System Fault

The combustion system is where the fuel, oxygen, and a spark unite to make a boiler work. As such, an F9 combustion system Ideal Logic Boiler fault code can refer to a problem in any of these areas. The gas supply can be blocked by debris, rust, or water. Equally, the gas pipes and their associated valves may be damaged. Oxygen supply to a boiler can be blocked by air bubbles, sediment, or water pressure issues. A range of factors can affect the spark, including damaged electrodes, wrongly adjusted gas pressure, and faulty valves. In all these cases, a professional can help.

Preventing Future Issues

Ideally, boiler issues should be prevented long before they escalate into an error code. Homeowners can take simple steps such as applying insulating foam to exterior pipes, ensuring good ventilation, and addressing any water hardness issues. Water harness varies across South London, with a general hardness of 296 ppm peppered with pockets of extremely hard water. This greatly increases the risk of limescale and, consequently, system damage. In addition to checking your water hardness, booking an annual Ideal Logic Boiler service is a proactive maintenance strategy that can identify any issues that may potentially evolve into problems, thus reducing the risk of expensive future repairs.

Next Steps

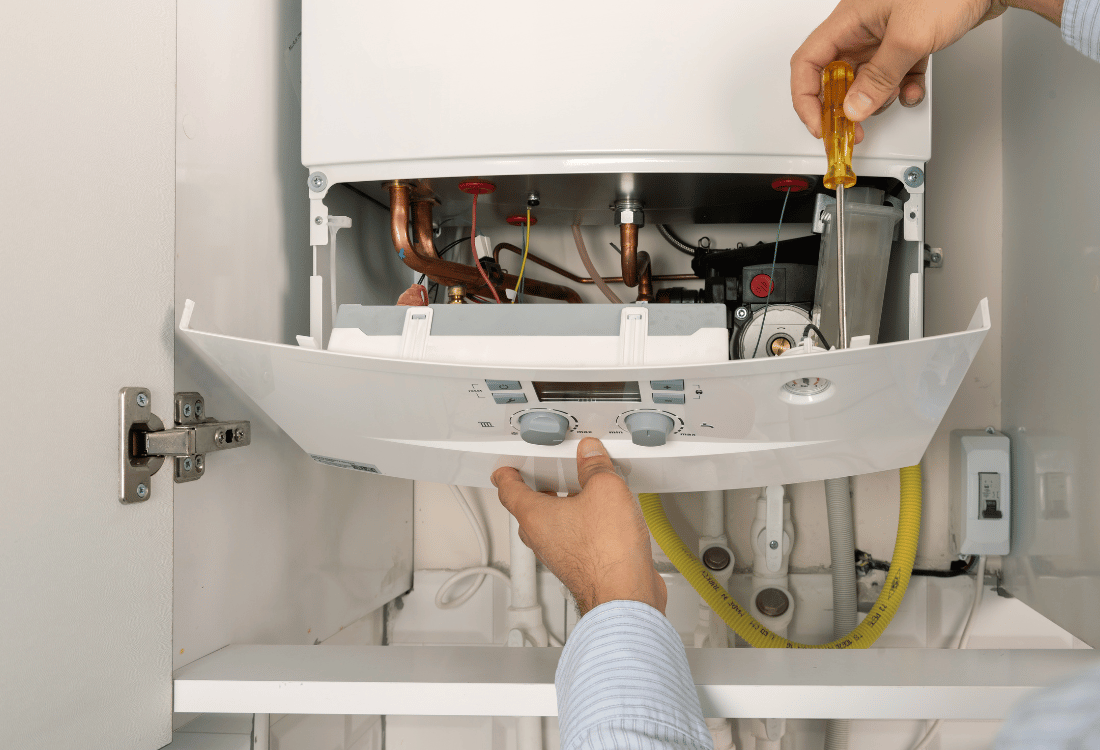

If you think that your Ideal Logic Boiler is showing signs of persistent faults or sluggish performance, don’t waste any time. To reduce the risk of needing professional help, book a boiler repair with one of our engineers today.

Image Source: CanvaSubscribe to our blog

You May Also Like

These Related Stories

3 Main Boiler Fault Codes To Look Out For During Winter

A Homeowner’s Quick Guide To Common Faults With Ideal Logic Boilers